博文

【论文】力控电纺丝工艺实现可控直写点-线微结构

|||

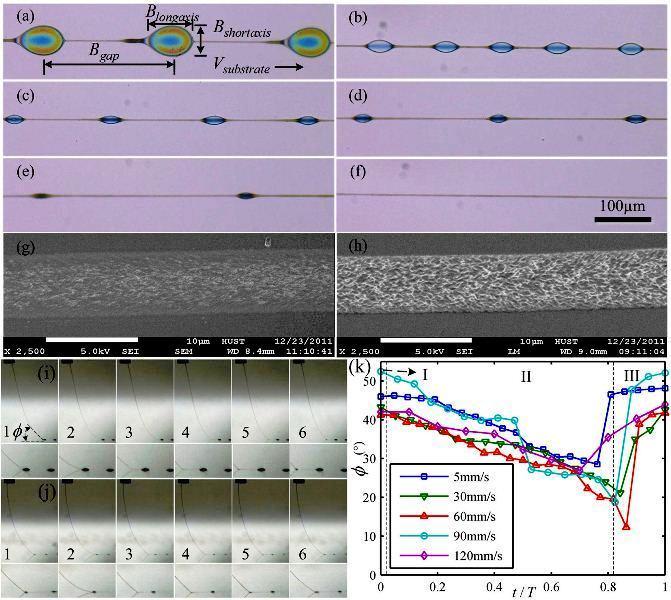

这篇论文主要是利用力控电纺丝方法的近场特点,纤维沉积到基板上时依然是液体,利用基板运动速度产生的纤维拉力和沉积在基板表面张力之间的竞争关系,实现点大小、间距的可控直写。并通过实验得到电纺丝直写的3个不同阶段。

力控电纺丝的基本思想是通过宏观的运动来控制微纳米纤维的定位和形貌,能够极大地提高电纺丝直写的可控性,并且由于机械拉力的存在,可以有效地降低电压,这有利于在聚合物上直接沉积结构,避免了被击穿。

Tunable bead-on-string microstructures fabricated by mechano-electrospinning, JOURNAL OF PHYSICS D: APPLIED PHYSICS,2012

论文地址:http://iopscience.iop.org/0022-3727/45/40/405301

直接下载:

【摘要】This paper presents mechano-electrospinning process to fabricate bead-on-string microstructures in a continuously tunable manner. The thin jet is pulled onto the substrate by the stable electric field force and tunable mechanical drawing force, then bead-on-string structures are generated by means of the force exerted on the jet at the contact point in the horizontal direction changes from capillary force, resisted viscosity force to friction force. When the mechanical drawing force in horizontal direction overtakes the surface tension, bead-on-string structures become continuous line structures by adjusting the substrate velocity. In stable formation process of the bead-on-string, one period can be divided into three stages from the point of view of jet behaviors: being anchored, being stretched, and skipping. The bead-size and the bead-gap are all continuously tunable through mechano-electrospinning process. The fabrication mechanisms of bead-on-string microstructure are uncovered through theoretical analysis and experimental characterization. When the critical velocity achieves, the combination of drawing force and electric field force leads the bead-on-string microstructures to continuous lines. It is a flexible and high-controllable method to fabricate bead-on-string microstructures.

https://wap.sciencenet.cn/blog-40956-613820.html

上一篇:【论文】基于纤维阵列形成的有限长度效应的点阵自组装工艺

下一篇:熊有伦院士招聘博士后(华中科技大学机械学院)