博文

【论文】力控电纺丝的可控直写纤维阵列

|||

好久没有来此发博文了,主要是不知道能写什么,一直好像是嘴尖皮厚腹中空。不过觉得科学网这个交流平台非常不错,时不时的有些朋友通过这里能够联系到我,我也想着以后能够慢慢的逐渐将我的自留地都种上蔬菜和水果。

后面慢慢与大家分享一些自己一些研究结果,与大家一起讨论,也希望大家能够多给一些建议。

论文:Continuously tunable and oriented nanofiber direct-written by mechano-electrospinning

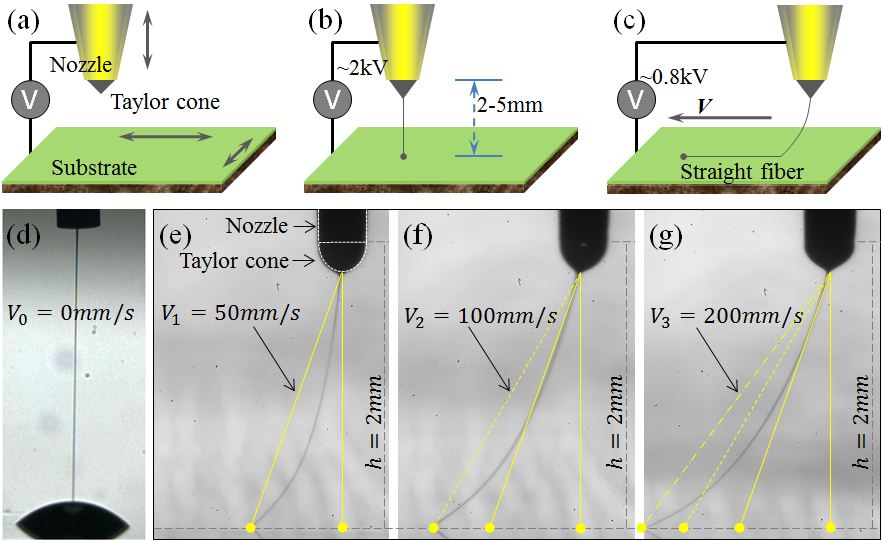

是在近场电纺丝基础上改进的一种方法,突出平台运动对电纺纤维的控制。利用运动平台的运动控制纤维直线度、直径,通过电极间距控制沉积“纤维”的形貌,如纤维和丝带。这样就可以利用平台的运动实现微结构的直写。这种电纺丝工艺注重的是运动平台对纤维的可控性,类似于风筝,通过类似于人的跑位和运动速度实现纤维定位和作用力的控制。

摘要:A mechano-electrospinning method is presented to direct-write oriented nanofiber with high deposition accuracy in continuously tunable manner. This method is able to use a large nozzle to deposit high-resolution fiber-arrays by near-field localization. Due to the existence of mechanical drawing force, a higher resolution pattern can be direct-written by a lower voltage, which just keeps the Taylor cone stable. Then the fiber is stretched through a moving substrate, by which the deposited fiber can be continuously tuned from 400 nm to 200 nm in a linear relationship. The effects of the speed on the diameter and morphology of fibers are studied, and the analysis of the mechanism of the fiber alignment is given. The positionability and controllability make mechano-electrospinning much different from the traditional electrospinning, which only collects the fibers in the form of nonwoven fabric. In addition, the fibers fabricated by this method can directly deposit over a large flat area in the form of arrays and complex patterns with high precision.

下图是运动平台不同速度下的对纤维的拉伸作用,类似于中国的风筝。

下图是通过基板速度和电极间距控制纤维的直径和形貌

https://wap.sciencenet.cn/blog-40956-607096.html

上一篇:【论文】柔性电子喷印制造:材料、工艺与装备

下一篇:【论文】基于纤维阵列形成的有限长度效应的点阵自组装工艺